These representative data were tested measured or calculated using standard methods and are subject to change without notice.

17 4 ph stainless steel data sheet.

Hardening is achieved by a short time simple low temperature treatment.

In these forms the alloy is supplied in condition a ready for fabrication and subsequent hardening by the user.

This page is mainly introduced the 17 4ph datasheet including chemical information mechanical properties physical properties mechanical properties heat treatment and micro structure etc.

Since the material transforms to.

Technical data sheet ati 17 4 ati 17 4 precipitation hardening stainless steel uns s17400 introduction ati 17 4 precipitation hardening stainless steel s17400 type 630 is a chromium nickel copper precipitation hardening stainless steel used for applications requiring high strength and a moderate level of corrosion resistance.

As sintered heat treated to h900 standard and heat treated to h1150 standard.

Al 17 4 precipitation hardening alloy is comparable to that of type 304 stainless steel in most media.

17 4 stainless is an age hardening martensitic stainless combining high strength with the corrosion resistance of stainless steel.

0 38 3 18 mm.

As with other precipitation hardening alloys al 17 4 pre cipitation hardening alloy is more susceptible to stress.

5 0 max.

It also contains the use of 17 4ph such as it is commonly used in bars sheet plates steel coils steel pipes forged and other materials application.

Alloy 17 4ph uns s17400 w.

17 4 ph stainless steel additional data values listed below compare markforged samples processed in three different ways.

Ak steel 17 4 ph stainless steel is produced in sheet and strip thicknesses from 0 015 0 125 in.

High strength 17 4 ph stainless steel with a higher chromium content than 15 5 ph stainless steel this high strength 17 4 ph offers better corrosion resistance.

Type 17 4 ph ams 5604 is the most widely used of all precipitation hardening steels and we are suppliers of 17 4 ph sheet coil and 17 4 ph round bar and plate.

In gen eral the corrosion resistance of al 17 4 alloy is supe rior to that of the hardenable 400 series stainless steels.

Stainless 17 4 ph 1 888 282 3292 upmet com type 17 4 ph stainless steel is the most widely used of all of the precipitation hardening stainless steels.

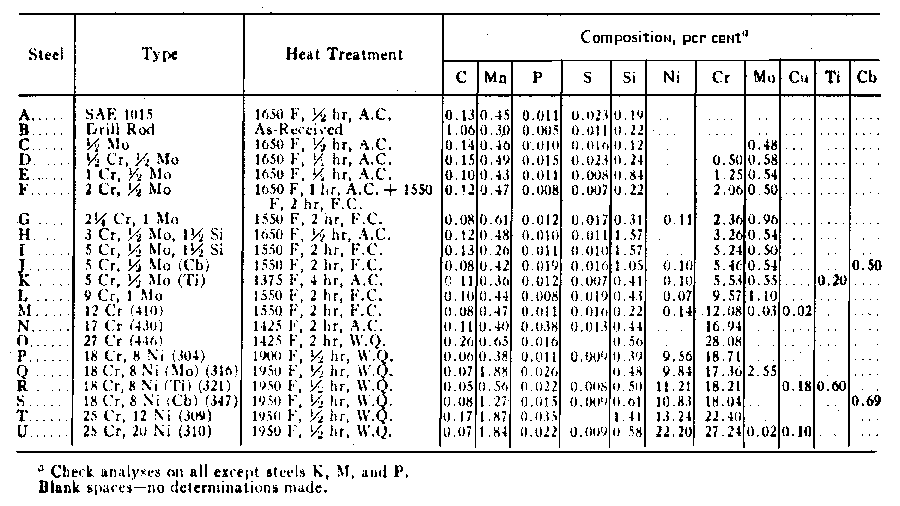

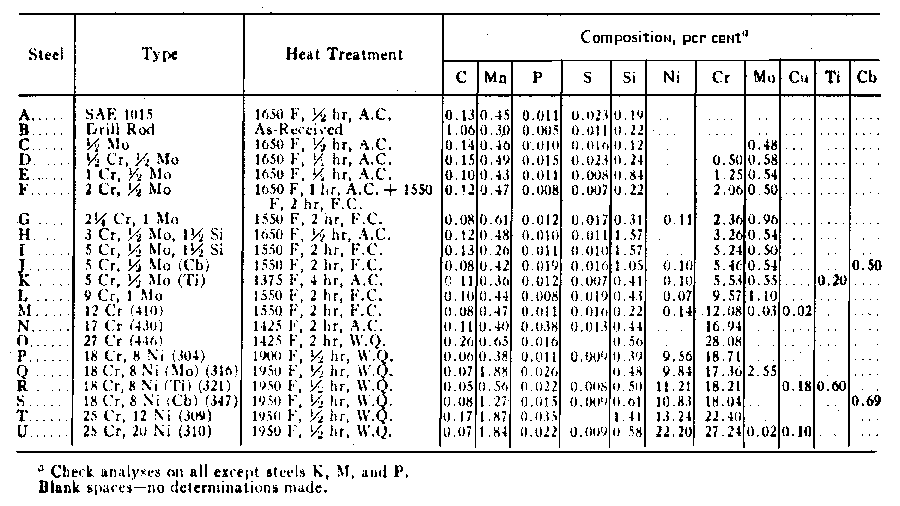

1 4542 type 630 a precipitation hardening martensitic stainless with high strength and hardness and good corrosion resistance chemical analysis weight all values are maximum unless a range is otherwise indicated chromium 15 0 min.

Phosphorus 0 04 nickel 3 0 min.

Unlike conventional martensitic stainless steels such as type 410 17 4 is quite weldable.