It is 20 percent stronger than 1100 series aluminum which is why it s a preferred metal and used for various applications in different industries.

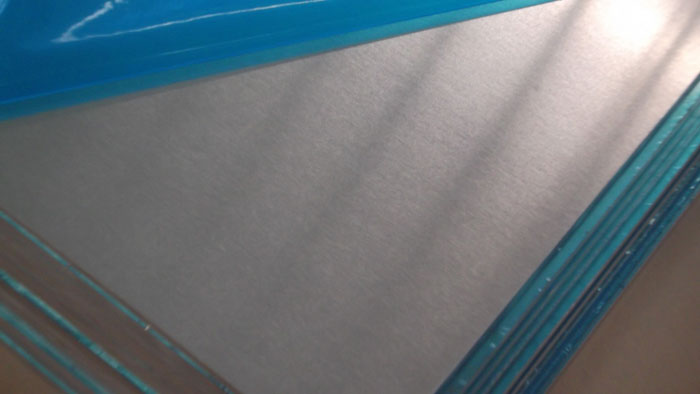

3003 h14 aluminum sheet specifications.

Aluminum alloy 3003 contains about 1 25 manganese and 0 1 copper which increase the strength approximately 20 above the 1000 series aluminum grades.

It has great resistance to corrosion can be welded easily and has excellent workability.

0 the above values are average and may be considered as representative of 3003 h14.

Aluminum 3003 product guide.

Browse aluminum sheet and coil series 3003 h14 in the continental steel tube co.

You have no items to compare.

3003 h14 020 aluminum sheet compare products.

Prices features and specifications are subject to change without notice.

The 3003 aluminum sheet with h14 temper has an unpolished mill surface meets sae aerospace material specifications ams qq a 250 2 and american society for testing and materials international astm b209 specifications and has a standard tolerance.

3003 aluminum is is highly workable formable and weldable with exceptional corrosion resistance.

The 3003 h14 aluminum plate is a medium strength alloy that is made with 1 20 percent manganese.

Aluminum 3003 uns a93003 in coil form.

Used for sheet metal work fuel tanks and other applications that require a slightly higher strength than 1100 series aluminum.

3003 h14 aluminum sheet.

3003 has excellent workability weldability and corrosion resistance.

Zoom 3003 h14 020 aluminum sheet.

3003 is alloyed with 1 2 maganese to provide a tensile strength range of 17 to 30 ksi.

Applications aluminum 3003 specifications related videos mechanical and chemical data.

3003 h14 aluminum sheet properties.

Aluminum sheet metal comes in a variety of thicknesses and weights in many different grades.

3003 h14 aluminum sheet.

Catalog including item shapeform thickness size sheet weight per unit area.

It is an alloy that is particualrly popular for outdoor projects that require extensive forming or joining operations.

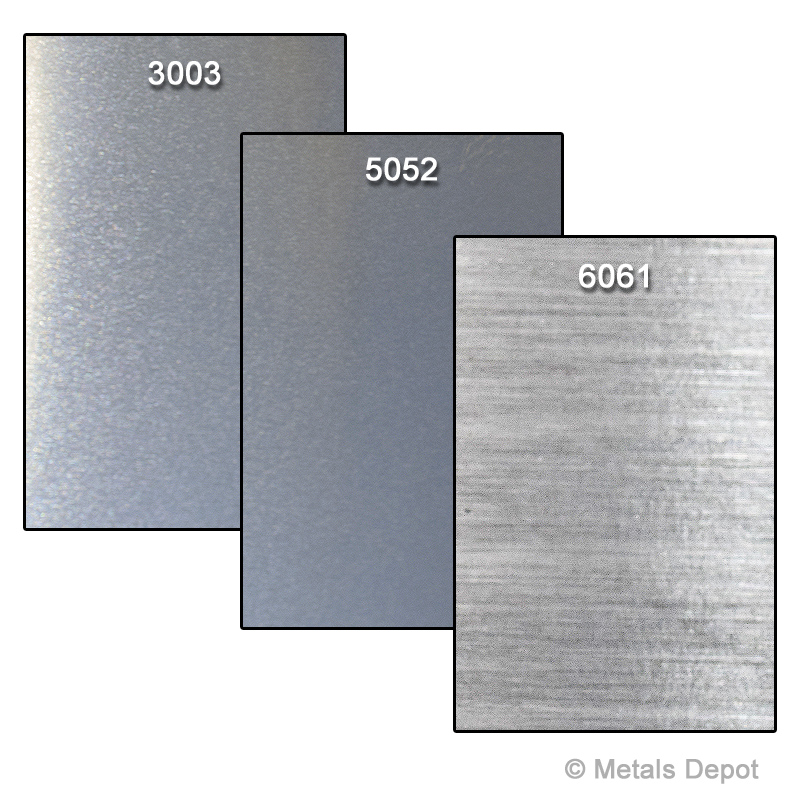

Ryerson offers heat treatable aluminum sheet grades like the popular 6061 aluminum alloy that can be used for commercial applications that require strength corrosion resistance and machinability as well as non heat treatable grades when formability and weldability are priorities.

Min 90 degree cold bend radius for 064 thick.

This is the most widely used of all aluminum alloys and it has all the excellent characteristics of alloy 1100 with higher strength.